The Rise of polypropylene eco-friendly: Revolutionizing Packaging and Industrial Applications

5 Mins Read

Published on: 24 July 2023

Last Updated on: 07 December 2024

toc impalement

In recent years, there has been a significant rise in the use of polypropylene eco-friendly. It is revolutionizing the world of packaging and industrial applications.

This versatile and sustainable material offers many benefits, making it a preferred choice for various industries. From reducing environmental impact to enhancing durability and versatility, polypropylene fabric has transformed packaging and industrial processes.

In this article, we will explore the rise of polypropylene eco-friendly and delve into its applications in the industrial sector.

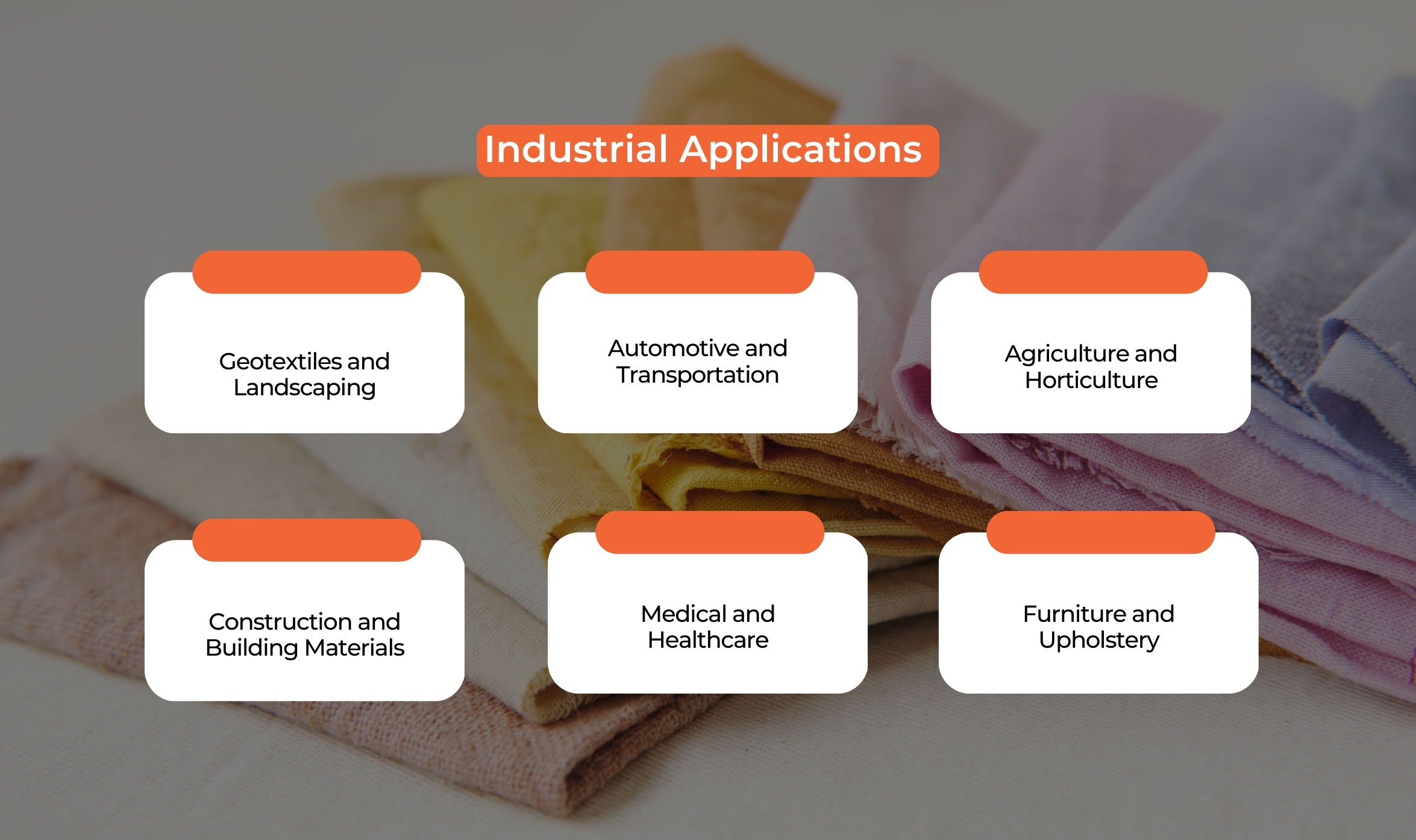

Industrial Applications

The remarkable rise of polypropylene eco-friendly has revolutionized the world of packaging and industrial applications.

This versatile material, known for its durability, lightweight nature, and recyclability, has gained significant traction across various industries.

Join us as we delve into the diverse industrial applications of this innovative material. Therefore, let’s explore the endless possibilities together.

1. Geotextiles and Landscaping

The eco-friendly polypropylene landscape fabric has found significant application in geotextiles and landscaping. Geotextiles from this fabric enhance soil stability, control erosion, and reinforce various civil engineering projects.

These fabrics act as a barrier to separate different soil layers, preventing mixing and maintaining soil integrity. Therefore, they also aid in drainage systems, filtration, and soil stabilization, making them ideal for road construction, embankments, and slope erosion control.

The fabric’s permeability also allows water and nutrients to penetrate while preventing weed growth, making it a sustainable choice for landscaping projects.

2. Automotive and Transportation

The rise of polypropylene eco-friendly has significantly impacted the automotive and transportation industries.

It offers durability, resistance to stains and spills, and ease of maintenance. Hence, polypropylene fabric’s lightweight nature also improves fuel efficiency, making it an environmentally conscious choice.

Moreover, it provides excellent resistance to fading and UV radiation, ensuring long-lasting aesthetics and performance in various weather conditions.

3. Agriculture and Horticulture

It is crucial in crop protection, weed control, and soil stabilization. However, by using this fabric as ground cover, farmers can prevent weed growth, reduce the need for herbicides, and conserve soil moisture.

Polypropylene acts as a physical barrier against pests, reducing the reliance on chemical pesticides. Furthermore, polypropylene fabric is utilized to construct greenhouse structures, providing shade, insulation, and protection from harsh weather elements.

Its durability and resistance to degradation make it an ideal choice for long-term agricultural applications.

4. Construction and Building Materials

It is employed in producing geosynthetic materials, such as geogrids and geocells, which enhance soil stabilization, reinforce structures, and provide adequate drainage systems.

Due to polypropylene’s nature, the component is used in many different ways, such as roofing, waterproofing, etc. Its lightweight properties make it easier to handle during construction, reducing labor costs and improving overall efficiency.

Moreover, this eco-friendly fabric contributes to sustainable construction practices by reducing waste and promoting recyclability.

5. Medical and Healthcare

The rise of eco-friendly, nonwoven polypropylene fabric has significantly impacted the medical and healthcare sectors. This fabric is widely shared in the production of non-woven medical textiles. The most common ones include surgical masks, drapes, and gowns.

Its breathable and moisture-wicking properties comfort patients and healthcare professionals, while its barrier properties help maintain sterile environments. Polypropylene fabric is also used in wound dressings, bandages, and orthopedic supports, offering high strength, elasticity, and biocompatibility.

The fabric’s antimicrobial properties and resistance to staining and fading contribute to maintaining hygienic and long-lasting medical products.

6. Furniture and Upholstery

polypropylene eco-friendly has significantly impacted the furniture and upholstery industry. It is widely optimized for producing chairs, sofas, and other upholstered furniture items. This fabric offers durability, easy maintenance, and resistance to stains, making it suitable for high-traffic areas and households with children or pets.

Additionally, polypropylene fabric provides excellent color retention, ensuring long-lasting vibrancy and aesthetics in furniture. Its moisture-resistant properties make it resistant to mold and mildew, enhancing the longevity and hygiene of upholstered items.

Moreover, the fabric’s lightweight nature allows for easy handling during manufacturing and transportation processes, contributing to cost and energy efficiency in the industry.

Future Outlook and Innovations

The future outlook for polypropylene eco-friendly is auspicious, with continuous advancements and innovations on the horizon. As environmental concerns grow, various industries have an increasing demand for sustainable materials. Polypropylene fabric, with its eco-friendly properties and versatile applications, is positioned to play a significant role in the shift toward greener solutions.

In terms of packaging, developing biodegradable and compostable polypropylene fabric is an area of active research. Innovations in additive technology and manufacturing processes aim to create polypropylene fabrics that can break down naturally in a shorter period, reducing environmental impact.

Polypropylene eco-friendly fabrics are being actively considered for their reusable and recyclable nature. As a result, megacorporations are actively looking for ways to recycle polypropylene fabric. This can lead to a newer dawn when it comes to eco-friendliness and sustainability.

In terms of industrial applications, there is a continuous drive to enhance the performance characteristics of polypropylene fabric. Research and development efforts are focused on improving the fabric’s strength, durability, flame resistance, and thermal insulation properties. These advancements will enable its use in even more demanding industrial sectors, such as aerospace and electronics.

Overall, the future of polypropylene eco-friendly is promising, with ongoing innovations and growing market demand for sustainable materials. As technology advances and sustainability becomes a top priority, polypropylene fabric will continue revolutionizing packaging and industrial applications, paving the way for a greener and more environmentally conscious future.

Conclusion

The industrial applications of polypropylene eco-friendly have created a new era of sustainability and efficiency. Its lightweight nature, high strength, resistance to moisture and chemicals, and recyclability make it an ideal preference for various industries.

Whether it’s in manufacturing, automotive, agriculture, etc., polypropylene fabric offers unparalleled advantages. This versatile material has proven its worth in numerous applications, from protective packaging to geotextiles, filtration, and beyond.

As industries prioritize sustainability and eco-consciousness, the rise of polypropylene fabric is set to revolutionize industrial processes, paving the way for a greener and more efficient future.

Read Also:

Comments Are Closed For This Article