Innovative Trends in Commercial Concrete Construction

21 May 2025

5 Mins Read

Key Takeaways:

- The commercial concrete construction industry is evolving with new technologies and sustainable practices.

- Technological advancements are making construction projects more efficient and sustainable.

- Understanding recent trends can help businesses stay competitive in the construction market.

Commercial concrete construction is constantly changing. These changes are driven by different reasons.

These changes are typically driven by different technological advancements and a focus on sustainability.

Most of these things are driven by local small projects to large-scale developments at the global level.

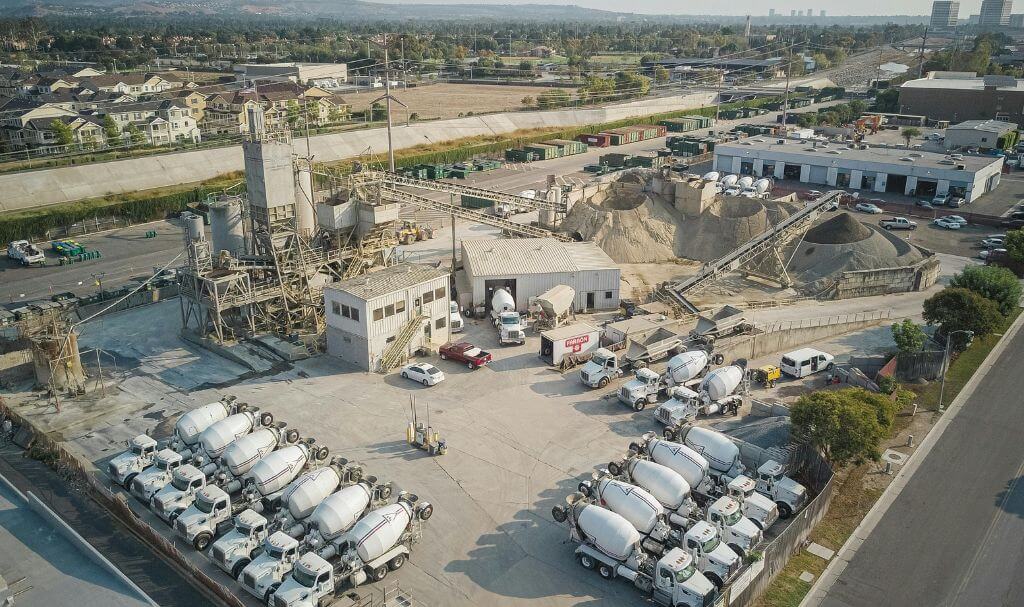

This change is visible across different companies and a vast industry. From large scale global companies to companies like Clark NJ commercial concrete contractor has started implementing these new changes.

These technologies pave the way for eco-friendly and future proof constructions with practices that align with them.

Why Follow Innovative Trends in Construction?

However, it’s not an option to follow the current trends. It’s a need for companies that want to thrive in a fiercely competitive industry.

Companies adopting these innovations can help in reducing the overall impact on the environment while also delivering value to the audience.

It’s not an option to follow the current trends. Typically, it’s a need for companies that are looking to thrive in specific industries.

It’s important since the organziation and consumers nowadays are looking for partners who share the overall value and are becoming more and more aware of sustainable practices.

The Rise of Precast Concrete

Let’s start with the case study of a popular concrete company in the construction industry. Precast concrete is a leading name in the construction material industry because of the different advantages these platforms provide.

This method involves producing concrete parts off-site and delivering them to the construction site for assembly.

It significantly accelerates project timelines by allowing multiple processes to co-occur. This method involves producing concrete parts off-site and delivering them to the construction stie for assembly.

It’s important and helps access project timelines by allowing different processes to happen simultaneously.

Moreover, since they produce the precast solutions in a controlled environment, these materials boast better quality control, contributing to more durable and reliable structures.

Concrete International’s discussion on the growing use of precast solutions highlights these advantages and underscores its role in pushing the boundaries of construction efficiency.

Self-Healing Concrete for Commercial Concrete Construction

Think of a material that can repair the damages and the cracks on it easily. If there are self healing concrete helping constructions stand tall and stay firm, it can help them reduce maintenance stress and long-term repairs.

Self-healing concretes are the blessings of technology to the world of commercial concrete construction.

It’s the promise of self healing agents such as bacteria, and certain chemicals. With this type of concrete, it’s easier to maintain constructions making it the most cost effective solutions in the commercial construction industry.

It’s still in the early stage of widespread commercial use, so, we are yet to see how it can help at a larger scale.

Meanwhile, construction companies that are using this new technology are rapidly seeing a great benefit and an increased level of longevity making it noteworthy development which could redefine the strategies of construction maintenance industry.

3D Printing on the Rise

When we think of advanced technologies transforming the construction industry, it’s important to think of reduced material waste, faster construction times, and a lower labor cost.

Precise Material Use: 3D printing allows for a reduced material waste at construction sites. Most construction sites incur significant cost from extra waste of raw material.

But 3D printing creates precise models, only using necessary amount of raw material for a component.

- Faster Construction: 3D printing makes it easier to build a house in a single day. It helps build portions of the building in parts that can be assembled later.

- Lowering Labor Cost: 3D printing is an innovation in the commercial concrete construction companies. In addition, initial investment in equipments are often high, through automation it’s easier to reduce labor needs, especially in places where it’s difficult to find skilled labor.

In addition, construction companies can also build more complex designs using the smart tech solutions that 3d printing provides.

Sustainability in Concrete Production

With the global push towards sustainability, exploring eco-friendly building practices has become a priority. The production of concrete, which has a significant carbon footprint, is now being approached more thoughtfully.

Innovations such as low-carbon concrete mixes, carbon capture technology, and recycled materials are leading the charge. ArchDaily highlights the importance of these initiatives in its articles on green building practices, emphasizing the industry’s role in global sustainability efforts.

In addition to being environmentally beneficial, reducing the environmental impact of concrete production is becoming increasingly crucial for regulatory compliance in several sectors.

Advanced Concrete Coatings

The development of advanced concrete coatings is enhancing durability and aesthetics.

These coatings defend against environmental elements, including moisture, ultraviolet light, and chemical exposure.

They increase the durability of concrete structures and guarantee that they maintain their aesthetic appeal over time when applied to exterior and interior surfaces.

Moreover, advanced coatings can contribute to energy efficiency by reflecting heat, making them popular for projects in warm climates.

The Importance of Digital Technology

Digital technology is becoming the cornerstone of modern construction projects. For instance, Building Information Modeling (BIM) is a powerful tool integrating different dimensions of a construction project into an overall digital platform.

Its capabilities include enhancing communication among project stakeholders, improving cost management, and reducing onsite errors.

By compiling all the data into a single model, BIM facilitates a synchronized workflow that is pivotal for large-scale or complex projects. As these tools advance, businesses can maximize their efficiency and production.

Future Prospects in Concrete Construction

Cutting edge technologies like AI, and machine learning can help in construction industries in the future. These technologies could also later on automate and optimize construction processes providing predictive insights and adaptive solutions to real-time challenges on-site.

Construction companies can harness these advancements and envision new designs and building methods. Thereby, it can help reposition concrete constructions at the very onset of innovation across industries.

Comments Are Closed For This Article